Pushing Beyond Military Specifications

Anytime a company mentions on social media that their products meet MIL-SPEC, someone inevitably makes the comment, "that just means crap quality, awarded to the lowest bidder". That's a bit of an exaggeration. But we also realize that the term MIL-SPEC often gets tossed around as a generic catch-all marketing term, like "artisanally crafted". So here's a deeper dive into the actual testing that Juggernaut.Case performs on our full range of products.

Purpose-Built Facilities

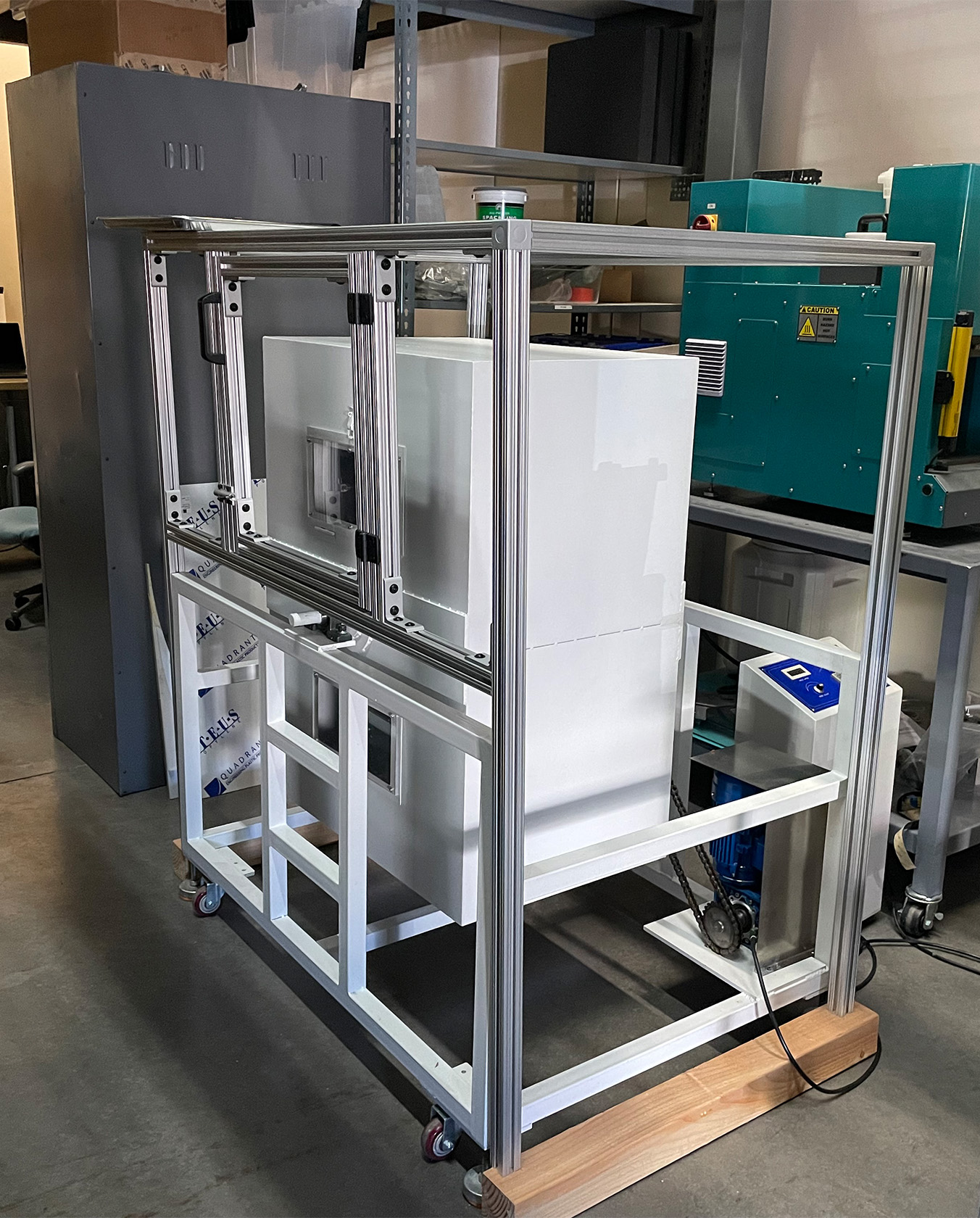

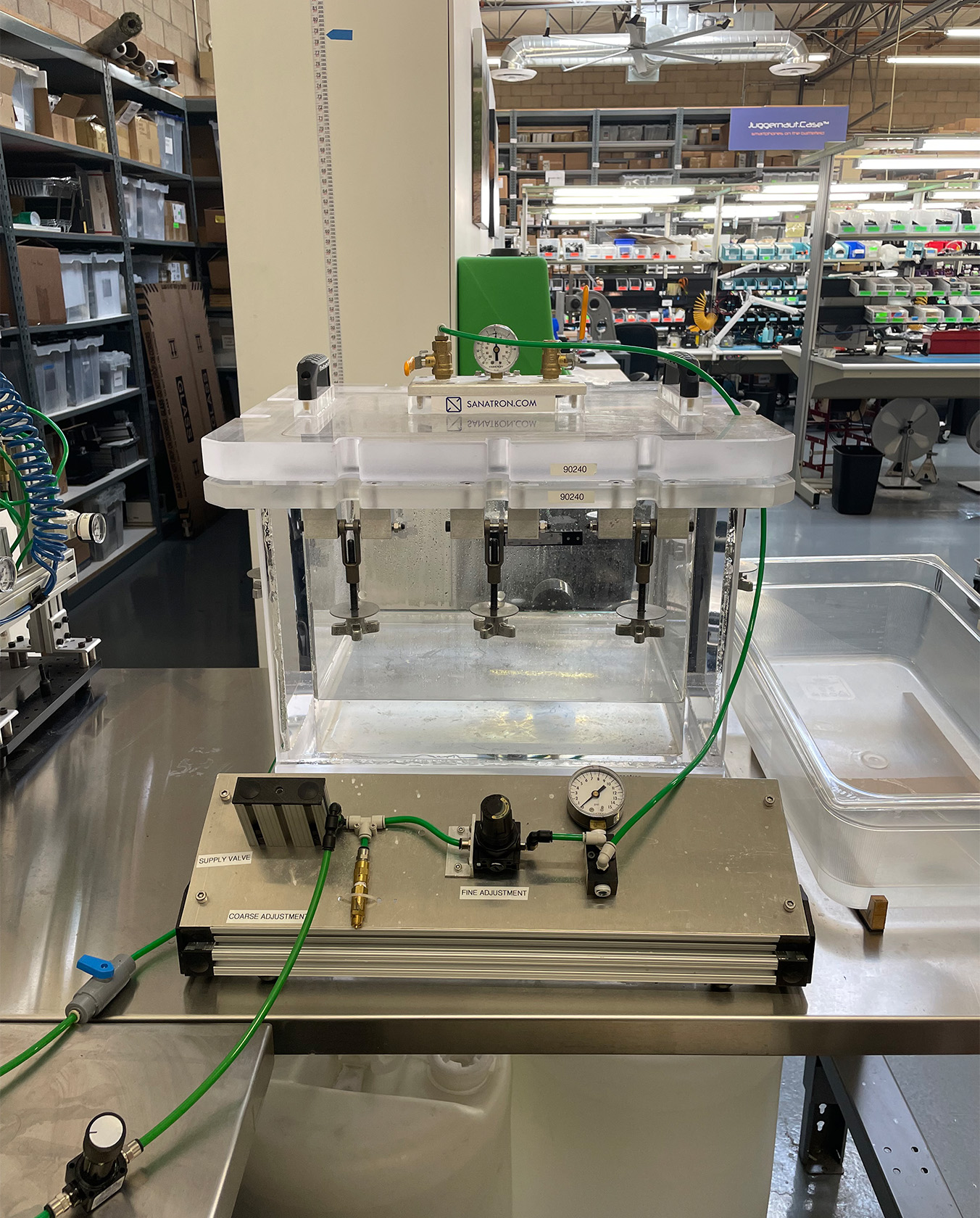

We utilize various tests to replicate a rugged environment. Depending on the type of product, we use MIL-STD-810G, MIL-STD-810H, and MIL-STD-202-203 as a starting baseline, and push the limits from there. Our in-house set up includes a fully equipped drop test studio, tumble tester, pressure chamber, vacuum tester, thermal chamber, cycle tester, and immersion tank.

PROTECT, MOUNT, CONNECT... TEST

CASES

IMPCT/SLEEV

MIL-STD-810G calls for a 4 foot drop onto concrete-backed plywood, 26 times across faces, corners, and edges, and allows for the test to be distributed over 5 devices. We perform the same test from 2 meters and with only 1 device.

ENDVR

MIL-STD-810H 516.8 Logistic transit- a 4 foot drop onto concrete-backed steel, 26 times across faces, corners, and edges, and allows for the test to be distributed over 5 devices. We perform the same test with only 1 device.

ADVNTR

We perform the same tests as ENDVR but in addition we also perform: MIL-STD-810H 516.8 Tactical Transport - a 5 foot drop onto concrete-backed 1 inch steel plate, 5 times across front face and edges. The test specification allows each drop to be performed on a different device, but we perform all drops for both tests on a single device.

OPRTR

We perform the same tests as the ADVNTR, but in addition we also perform: MIL-STD-810H 516.8 Severe Tactical Transport - a 10 foot drop onto concrete-backed 1 inch steel plate, 5 times across front face and all edges. The test specification allows each drop to be performed on a different device, but we perform all drops for all tests on a single device. MIL-STD-202 Method 203C Random Drop- the OPRTR with cell phone installed is placed in a tumble-tester, then rotated for 45 minutes at 4-6 revolutions per minute in a steel cage.

MOUNTS

Our mounts are designed and tested internally for specific de-mounting forces defined by their use case scenario. For example, an Armor.Mount that is worn on a tactical plate carrier has a higher release force requirement than our fitness Armband.Mount that requires a lighter force for a one-handed release.

Any hinged or articulating components are cycle tested to ensure operational longevity in the field.

We test the polymer components for full operability after exposure to sand, dust, water, and an array of industrial chemicals.

Temperature testing parameters range from high to low, and shock.

•High temp of 120 degrees Fahrenheit

•Low temp of -40 degrees Fahrenheit

•Shock from 120F to -40F within 30 minutes

CABLES

Most EUDs with a USB-C connector will shut down the charge port if water is detected, but with a sealed Juggernaut connector the charge port stays dry. All Juggernaut USB-C cables (including IMPCT cables) have a connector seal, making the connection to the EUD charge port IP67 rated (1M water immersion for 30mins). All QD cables are vacuum tested for Quality Assurance.

Cables terminating to any MIL-SPEC connector are IP67 rated at both ends. Unterminated cables are only IP67 rated at the Juggernaut end. Cables terminating to a standard USB-A connector are not rated on the IP scale.

Our strain relief has been designed and field tested to maximize the durability of cables being used in rugged environments.

All cables are inspected for continuity prior to shipping. Hipot testing available on request for some cables (fees may apply).

Cables are shielded end to end to provide maximum EMI (electromagnetic interference) protection. MIL-STD-461 testing (RS103 and RE102) has been performed on select cables for various customer-specific configurations, and can be tested upon request (fees may apply).

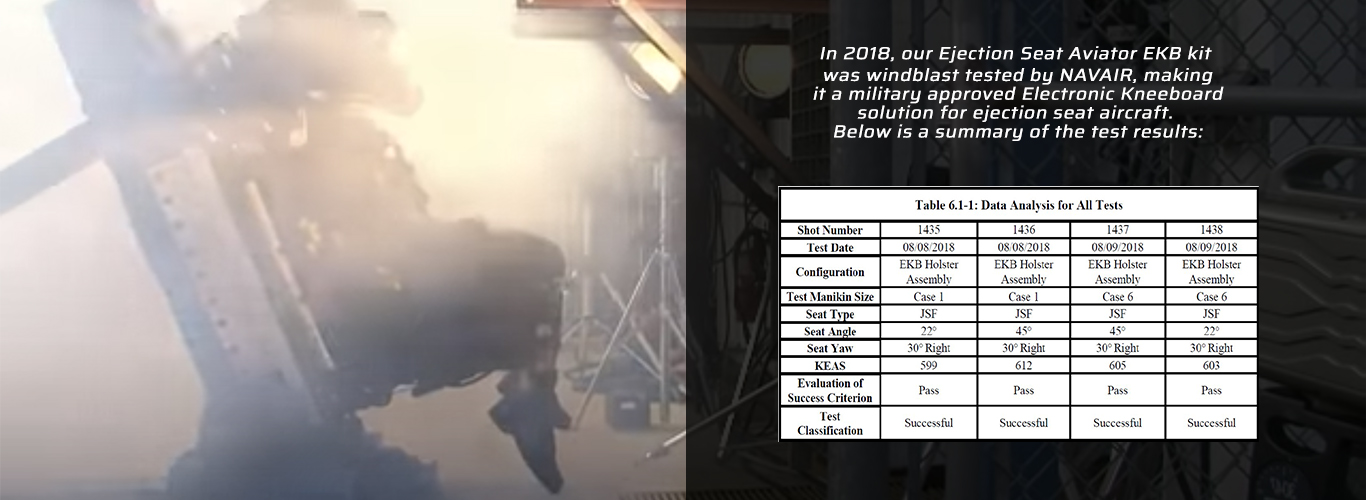

EJECTION SEAT KIT

PROTECT - CASES

Select models of Samsung, Apple, Google, Panasonic are currently supported with a range of case models. Visit our PROTECT page.

MOUNT - MOUNTS

From standard body or vehicle placement, to full MFF scenarios, there's a solution for almost any need. Explore them all on our MOUNT page.

CONNECT - CABLES

Designed for secure connection to our cases, power and data solutions cover standard or specialty integrations. See details on our CONNECT page.